gmf-eng

Mining and Metallurgical Faculty

The history of the development of the mining and metallurgical faculty is closely connected with the history of the formation of the Rudny Industrial Institute, which began in 1959. Over the years the existence of the Institute, MMF has made a huge contribution to the training of highly qualified specialists for the mining industry. Here are some milestones that characterize the main stages of its formation and development:

1959 – the first set was organized on a special basis: “Development of mineral deposits”, “Industrial and civil construction”, “Reinforced concrete constructions and building materials”;

1962 – the faculty consisted on an independent balance;

1964 – 1st graduation of civil engineers and mining engineers;

1968 – in order to improve the organization of the educational process, the faculty is divided into two faculties: construction and mining;

2002 – the Faculty of Civil Engineering after the joining of the departments “Mineral Extraction” and “Development of Mineral Deposits” was renamed as Construction and Technology;

2004 – the Faculty was renamed as Mining and Construction;

2012 – the Faculty was renamed as Mining and Metallurgical.

At various times, Kulikova GG, Kirov I.P., Pervushin N.G., Nazarov S.K., Zhanturin M.Zh., Osadchy V.I., Toyshybekov I.S. A.A., Kuzmin S.L. worked as faculty deans.

In different years Doctor of Geological and Mineralogical Sciences, Professor Ivlev A.I., candidates of technical sciences, associate professors Maulyanbaev T.I., Maltseva Z.D., Vladimirova E.V., Ryabtsev KG, Ansabaev A.A., Mikhailovsky AI, Kozlovskikh AI, Kuznetsov N. G., Khvan L.I., Zhivaykin IG, Abdrakhmanova DK, Barulin AI, Candidate of Technical Sciences Rakhimov Z.R., Bayuk O.V., Associate Professor Kirov I.P. taught at the institute

Currently, the faculty conducts training in four specialties:

- 5В070700- “Mining (specializations:“ Open mining of mineral deposits ”,“ Underground mining of mineral deposits ”,“ Mine surveying ”);

- 5В070900 – Metallurgy;

- 5В071300 – Transport, transport equipment and technology;

- 5В073700 – Mineral Processing

The faculty is staffed by highly qualified specialists, including Doctor of Technical Sciences, Professor Naizabekov A.B Candidate of Technical Sciences, Associate Professor Lezhnev S.N., Candidate of Technical Sciences Kuzmin S.L., Verin S.V., Fionin E.A., Candidate in Physics and Mathematics Sciences Shaldykova BA, Arepyeva S.V., Candidate of Political Sciences Tazhibaev R.H. In recent years, young masters came to work at the faculty department: Salko O.Yu., Iskakov R.Zh., Nurmukhambetova G.T., Askarova R.A., Kattygarin Zh.N. etc.

Training is conducted in the state and Russian languages. For college graduates it is provides an abbreviated form of education. The faculty has 46 groups. The total number of students is – 468, which 176 – have a grant.

The students are provided with 43 studying rooms, and 17 are laboratories. Computer rooms are equipped with the latest generation computers.

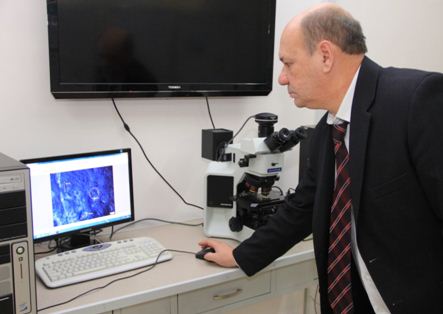

The special pride of the faculty is a laboratory for studying the properties of metals and rocks. It is equipped with an OLIMPUSVH-53M microscope and the SAPHIR 520 grinding and polishing machine for preparing thin sections for microscope studies. Students can review and study the structure of the metal and rock.

To determine the chemical composition of the metal and rock there is a ThermoNiton X-ray fluorescence spectrometer using a miniature X-ray tube technology and a solid-state detector. The high speed of multi-element analysis and at the same time the reliability and accuracy of the results obtained can significantly reduce the measurement time and save money, in most cases, refuse to use complex laboratory research methods. In addition, portability, ease of use and the ability to analyze samples of any kind of material, shape and size, as well as heated or vibrating objects, make the device ideally suited for working in production conditions and in field conditions.

In order to improve the quality of teaching, the Administration of the Rudny Industrial Institute acquired a modern laboratory stand from the concern FESTO, which is a recognized world leader in the creation of components of hydraulics, pneumatics and automation. The main feature and advantage of this laboratory is that it works according to the principle of the designer. So, the stand includes components that can be combined in various combinations. This principle activates the independent work of students, allows to evaluate the advantages of the aggregate-node principle of work of modern industry.

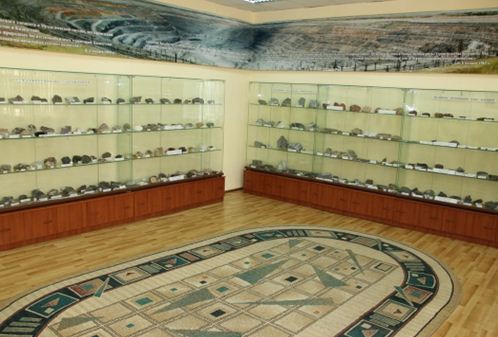

The geological museum, created and equipped with the Department of Metallurgy and Mining, collected rocks and minerals not only from the fields of Kazakhstan, but also from fields in many countries. Alexander Ivanovich Ivlev, a doctor of geological and mineralogical sciences who worked at the department, and Raisa Valentinovna Shitova, who worked at the department, played an important role in creating the museum.

In 2015, the Metal Rolling Laboratory was created, in which the SVP-08 industrial screw mill and a tubular furnace by the German company Nabertherm were installed. In the laboratory, students of the specialty Metallurgy conduct classes in the disciplines “Metal Forming”, “Rolling Production Technology” and carry out research projects of diploma projects.

To control the operation of the equipment, non-destructive testing equipment is currently being implemented in production, and graduates of the institute conduct research on ultrasonic flaw detectors and a vibration meter from the American company Fluke.

A modern Fluke-810 vibration meter for the diagnosis of mechanical equipment is capable of instantly producing measurement results. It monitors unscheduled failures in equipment operation, prevention of preventing similar problems and solving priority tasks during repairs, maintenance and periodic inspections. With the help of unique technologies and capabilities of the device, it is possible to perform diagnostics of mechanical equipment very quickly and efficiently.

In honor of the 50th anniversary of our university, JSC SSGPO donated to the department of M&M a class equipped with modern geodetic and surveying devices used in the training of specialists – surveyors.

Since 2015, computer technologies have been widely introduced into the learning process at the MMF specialties, which make it possible to see the complex processes occurring during smelting, become familiar with the design of mining equipment, make a virtual assembly and disassembly of equipment.

To simulate the research conducted in the departments there are software products:

– SimufactForming13.0 – computer simulation system for calculating the processes of metal deformation in the processes of forging and die forging when designing die tooling. SimufactForming allows you to optimize temperature and speed, taking into account the stress-strain state, the conditions of the processes, to design the optimal technology. This is facilitated by the adequacy of the models of the technological process, as well as an accurate description of the rheological behavior of the metal under conditions of deformation. From forging to rolling, from sheet metal to titanium – all tools are available in SimforForming for effective modeling and calculation, regardless of process temperature, equipment used or materials processed. This program is used for students of the specialty “Metallurgy”

APM WinMachine is a computer-aided design and engineering system for mechanical equipment and structures in the field of mechanical engineering, developed with account of recent advances in computational mathematics, the field of numerical methods and programming, as well as theoretical and experimental engineering solutions. The APM WinMachine software product is built according to a modular scheme, which provides convenience in its use for highly targeted industrial engineering tasks.

All modules are divided into four thematic groups:

– Graphic tools (2D and 3D preprocessor for preparing geometry for calculations);

– Machine parts and connections (calculations of standard machine parts, mechanisms, as well as their connections, both detachable and non-detachable);

– Finite element analysis (analysis of strength, stability, intrinsic and forced dynamics of structures under static and dynamic force and temperature effects);

– Databases (arrays of reference information in text and graphic views on the parameters of materials, standard sections of metal, etc.).

The program is used by students of mechanical specialties of the faculty.

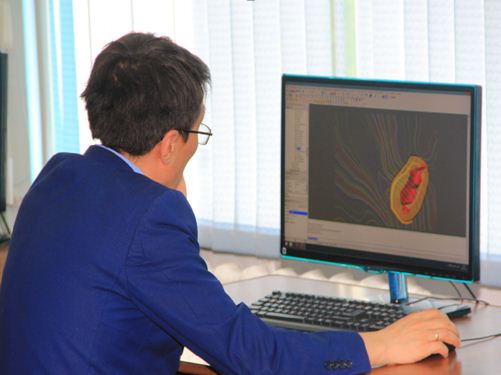

For students of mining specialty in the educational process introduced GIS Surpac and GGIS Micromine, allowing the design of mining operations.

GEOVIA Surpac is the world’s most popular software for geology and mine planning in quarries and underground mines, as well as for supporting exploration projects in more than 120 countries. This software provides efficiency and accuracy due to ease of use, powerful three-dimensional graphics and automation of workflows, taking into account the specifics of the processes and data flows of a particular company. Surpac meets all the needs of geologists, surveyors and mining engineers in the primary sector and adapts to any raw material, ore body or mining method. Multilingual interface allows companies to use the same solution worldwide.

The program for 3D modeling of deposits Micromine is a comprehensive solution for 3D modeling of deposits, offering tools for assessing the fields, designing, optimizing and planning mining. The system provides users with a comprehensive overview of the project, so you can focus on a more thorough study of promising areas, increasing the chances of success.

Micromine consists of 10 modules. The scalability and component structure of the program allows you to choose the Micromine functionality that the company needs at the moment. New compatibility with 64-bit system provides work with large data arrays than before.

An important part of the activities of the faculty for the preparation of bachelors is a methodical work. It is aimed at ensuring the educational process and includes the compilation of textbooks in the disciplines of the specialty, development of course and degree projects (works), instructions for performing control work, laboratory classes, practical training programs, etc.

Practicing is the compilation of methodical developments with the receipt of external reviews of major leading universities and industrial enterprises. A number of benefits released through the methodical office of the Ministry of Education. The teachers of the faculty prepared the textbooks:

– Naizabekov A.B. General metallurgy. Study Guide, 2015;

– Maulyanbaev T.I. Fundamentals of opencast mining technology, 2016;

– MaulyanbaevT.I. Russian-Kazakh-English mining technical dictionary, 2016;

– Ovchinnikova G.V. Mining mechanic for underground works. Astana, 2015.

For the control and management of methodical work it is operates the methodical commission of the faculty. It is headed by the senior teacher of the department of MGD Skalozubova G.V. According to the proposals of the department, the MCF examines and makes changes to the working curricula, controls the methodological security of the disciplines, approves the methodological developments, examines the compliance of the level of teaching specialty disciplines with the requirements.>

An integral part of the activities of the faculty is research work. The departments of the faculty are actively engaged in state budget and contractual works.

The state budget themes of the departments at the faculty correspond to the integrated research area of the institute: “Socio-economic, scientific and technical problems of rational use of natural resources and ecology of North-West Kazakhstan.”

According to the results of research, scientific articles, reports and inventions are being prepared for publication. Thus, for the period since 2012, faculty teachers published over 500 scientific articles in the open press. GMF teachers take an active part in scientific conferences at various levels. Over the past 6 years, 5 topics on grant financing of the Ministry of Education and Science of the Republic of Kazakhstan were carried out at the GMF, which received high marks during external and internal expertise.

One of the main directions in the work of the dean’s office is educational work. She is coordinated by the deputy dean for educational work. Over the years, this position was occupied by Burdakova ON, Suyubayeva Zh.T., Duysenov E.D., Kenzhegalieva Zh.L.

The task of educational work is to hold mass events, patriotic education of young people, explaining to the students the state policy and individual work with students.

The Mining and Metallurgical Faculty is proud of its graduates, many of whom currently hold high positions in the city of Rudny, the Republic of Kazakhstan and beyond its predecessors.

Proof of the high quality of training are the victories of students in republican competitions of research works and graduation projects in the specialties of the faculty.

The Faculty of Mining and Metallurgy maintains relations with many universities and enterprises of Kazakhstan and the near and far abroad. He has creative connections with academic research institutes and enterprises.